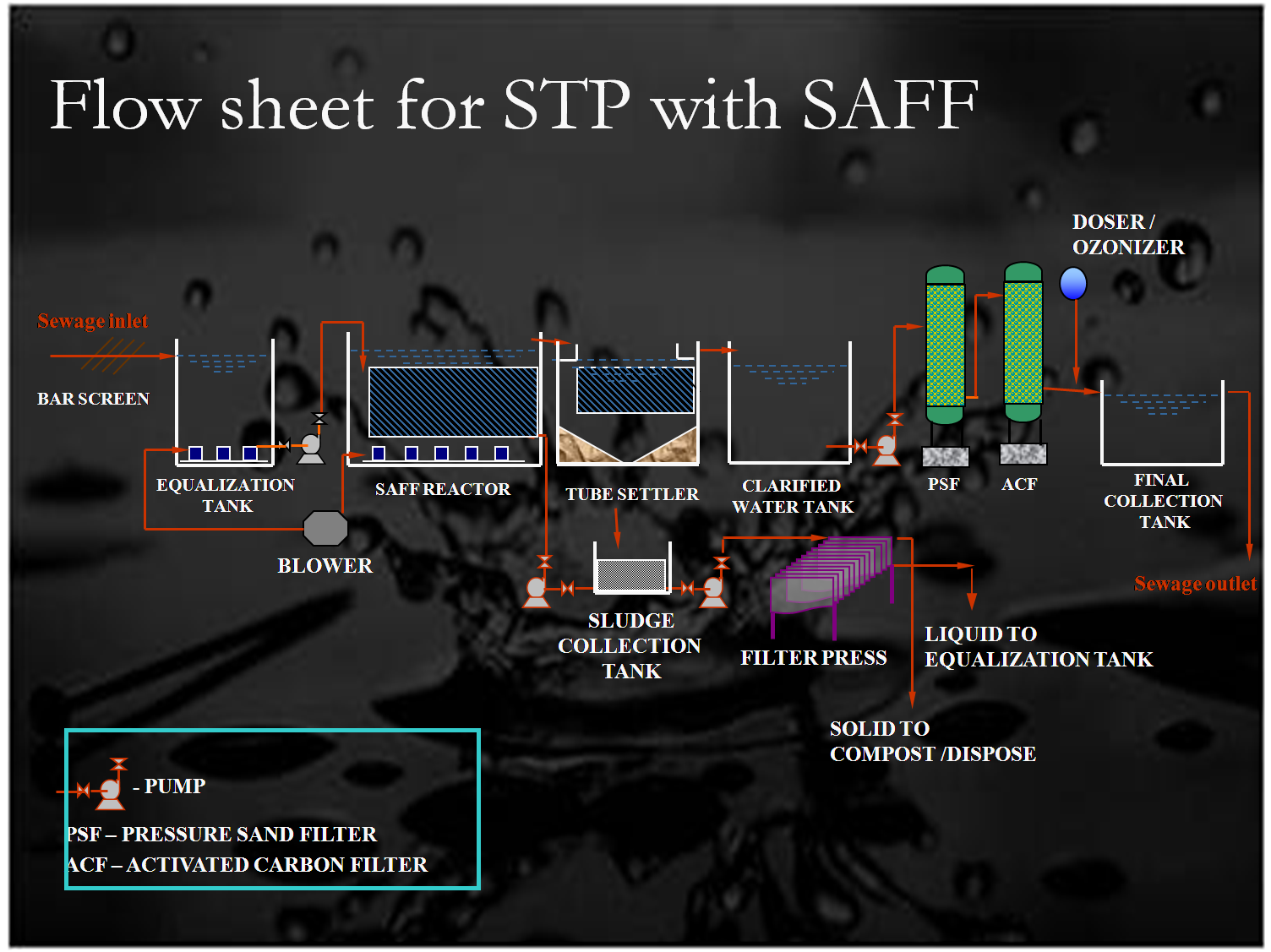

Sewage and Effluent Treatment Plant

We Design, Manufacture, Supply, Erect and Commission Effluent Treatment Plant (ETP) on Turnkey basis for various types and natures of wasteWaters, effluents which combines advanced physico-chemical treatment processes with tertiary polishing system for the removal of organic, inorganic, oil and grease, heavy metals & suspended solids.

We analyze the effluent samples for different effluent parameters as per nature and compositions, carry out the treatability studies by using different methods checking techno-commercial Feasibility and then designed treatment schemes, processes accordingly to suit the purpose and need.

Our ETP systems are very compact, tailor made designs, portable required very less foot-print to accommodate, energy efficient. The up-gradation, modification in the existing ETP system is possible to achieve desired limiting standard laid down by the Pollution Control Board (PCB).

Processes in ETP and STP may be generally grouped under six methods:

- Preliminary Treatment

- Primary Treatment

- Secondary Treatment

- Disinfection

- Sludge Treatment

- Tertiary Treatment

Preliminary Treatment

At most plants preliminary treatment is used to protect pumping equipment and facilitate subsequent treatment processes. Preliminary devices are designed to remove or cut up the larger suspended and floating solids, to remove the heavy inorganic solids, and to remove excessive amounts of oils or greases.

To effect the objectives of preliminary treatment, the following devices are commonly used:

- Screens -- rack, bar or fine

- Comminuting devices -- grinders, cutters, shredders

- Grit chambers

- Pre-aeration tanks

In addition to the above, chlorination may be used in preliminary treatment. Since chlorination may be used at all stages in treatment, it is considered to be a method by itself. Preliminary treatment devices require careful design and operation.

Primary Treatment

Variations in design, operation, and application, settling tanks can be divided into four general groups:

- Septic tanks

- Two story tanks -- In-house and several proprietary or patented units

- Plain sedimentation tank with mechanical sludge removal

- Upward flow clarifiers with mechanical sludge removal

When chemicals are used, other auxiliary units are employed. These are:

- Chemical feed units

- Mixing devices

- Flocculators

Secondary Treatment

In secondary treatment may be divided into four groups:

- Trickling filters with secondary settling tanks

- Activated sludge and modifications with final settling tanks

- Intermittent sand filters

- Stabilization ponds

Sludge Treatment

This is accomplished by a combination of two or more of the following methods:

- Thickening

- Digestion with or without heat

- Drying on sand bed -- open or covered

- Conditioning with chemicals

- Elutriation

- Vacuum filtration

- Heat drying

- Incineration

- Wet oxidation

- Centrifuging

Though specific limitations have not been established, individual package units have, in general, been small installations serving a limited population. Package units have been adapted to practically all the treatment devices, either singly or in various combinations that have been mentioned.

Tertiary and Advanced Wastewater Treatment

Tertiary treatment has been used to describe processes which remove plant nutrients, primarily nitrogen and phosphorous, from wastewater.

Improvement and upgrading of wastewater treatment units as well as the need to minimize environmental effects has led to the increased use of tertiary treatment.

A term that is also sometimes used to indicate treatment of a wastewater by methods other than primary or biological (secondary) treatment is advanced treatment. This degree of treatment is usually achieved by chemical (for example coagulation) methods as well as physical methods (flocculation, settling and activated carbon adsorption) to produce a high quality effluent water.

Waste Water Recycling

Sewage treatment is the process of removing contain household sewage, both runoff (effluents) and don chemical, and biological processes to remove physical, chemical and biological contaminants. Its objective is to produce an environmentally safe fluid waste stream (or treated effluent) and a solid waste (or treated sludge) suitable for disposal or reuse (usually as farm fertilizer).

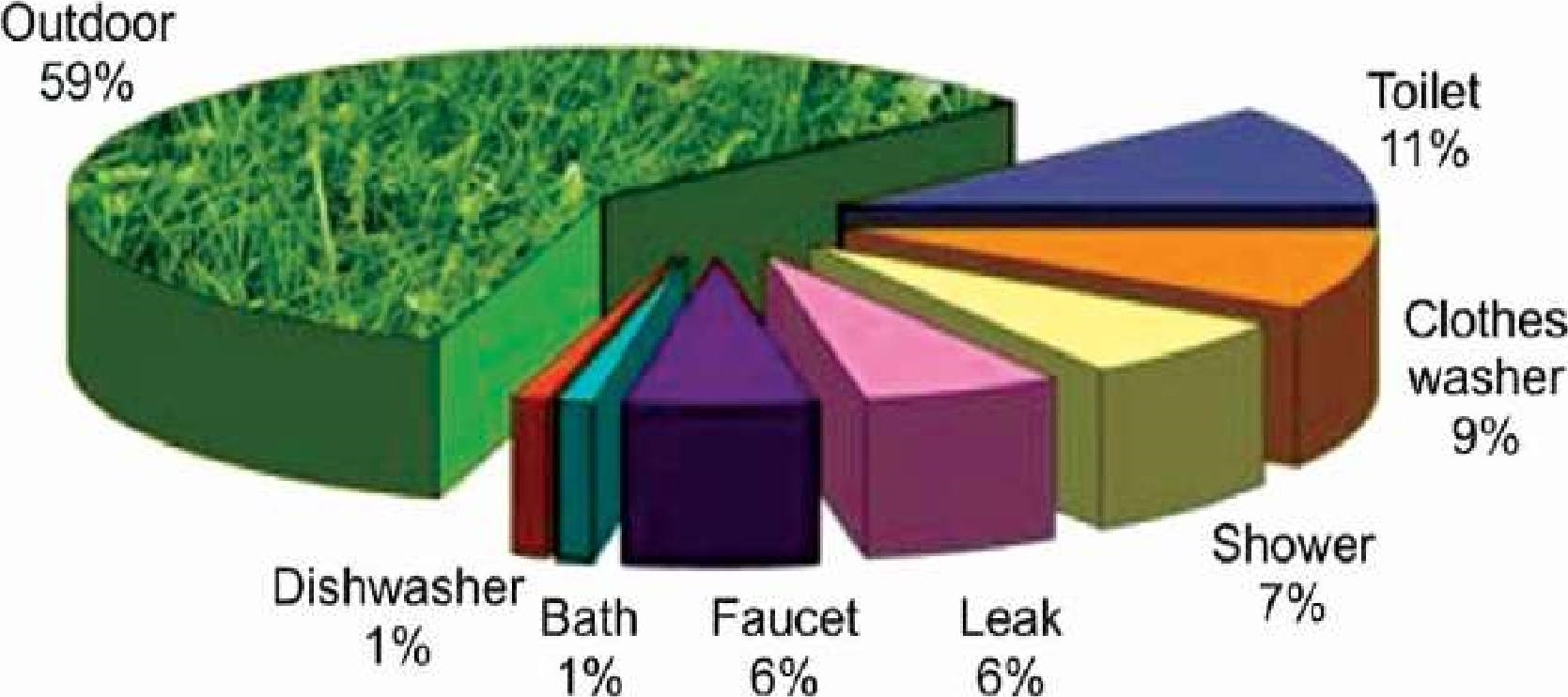

Grey Water Recycling

Greywater or sullage is all wastewater generated in households or office buildings from streams without fecal contamination, i.e. all streams except for the wastewater from toilets. Sources of greywater include, sinks, showers, baths, clothes washing machines or dish washers. As greywater contains fewer pathogens than domestic wastewater, it is generally safer to handle and easier to treat and reuse onsite for toilet flushing, landscape or crop irrigation, and other non-potable uses.

Residential Average Water Use

MAJOR BENEFITS OF GREY WATER RECYCLING & USE ARE

- Reducing the need for fresh water has a broader community benefit in reducing demands on public water supply.

- Reducing the amount of wastewater entering sewers or on-site treatment systems. Again, this can benefit the broader community.

- Significantly reduced water costs.

- Reduced environmental impact.

- Daily supply per person roughly equates to demand — no reliance on rainfall.