Water Treatment Plants

FILTRATION

The filtration process involves flow of water through graded & specially selected media. This filter media blocks passage of contaminants through physical obstruction, chemical adsorption, or a combination of both processes. EWS offers filters which are widely appreciated for their host of qualitative features such as durability, reliability and sturdy construction. These Industrial Water Filter plants are manufactured using qualitative raw material sourced from reliable vendor. The entire range is thoroughly tested so that they supply water free of applicable contaminants

EWS offers the following filters as per clients requirement

1. Multigrade Sand Filter2. Pressure Sand Filter

3. Activated Carbon Filter

4. Iron Removal Filter

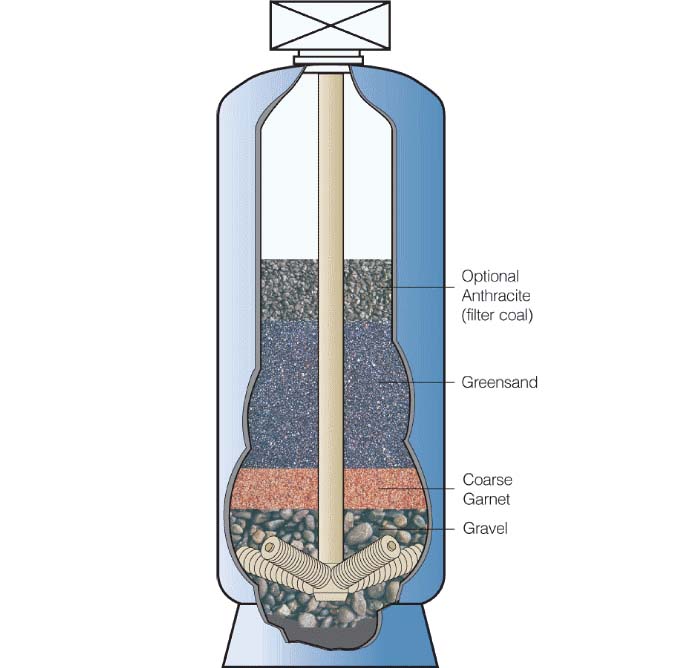

Iron Removal Filter

The presence of iron is probably the most common water problem faced by consumers and water treatment professionals. The maximum secondary contaminant levels for iron and manganese are 0.3 mg/l and 0.05 mg/l, respectively. Iron and manganese in excess of the suggested maximum contaminant levels usually result in discoloration of water, laundry, and plumbing fixtures. Rusted and damaged pipelines are a major cause of iron in the water. The presence of iron in water can pose considerable design, cost, and operational issues to industrial processes. EWS iron removal solutions provide an effective, economical way to removing iron from water.

Filter Layers: MnO2, Quartz Sand, White Sand, Activated Carbon Granules, Silex & Pebbles.

Target Impurities :-

1. Iron as Fe2. Turbidity

Advantages :-

1. High Filtration efficiencies2. Filter up to 10 – 20 Microns

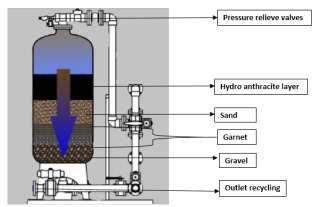

Multigrade Filter

The multi-Grade filter (MGF) is generally used for the pre-treatment in a purified water system.MGF removes the solid suspended particles from water. It has a longer life and requires low maintenance costs.Multi-grade filters are used in water and wastewater treatment to remove the solid particles, dust, and dirt present in water. It consists of multi layers of filter media consisting graded sand, wbhite sand, fine sand,and pebbles layers, which retain the suspended particles As the water passes through the various media layers, the filtration takes place, and it retains all the dust and suspended particles, and the water flows out of the filter outlet.

Filter Layers: Graded Quartz Sand, Fine white sand, Activated Carbon granules- IV 950gms, Pebbles

Target Impurities :-

1. Suspended solids2. Turbidity

Advantages :-

1. High Filtration efficiencies2. Filter up to 10 – 20 Microns

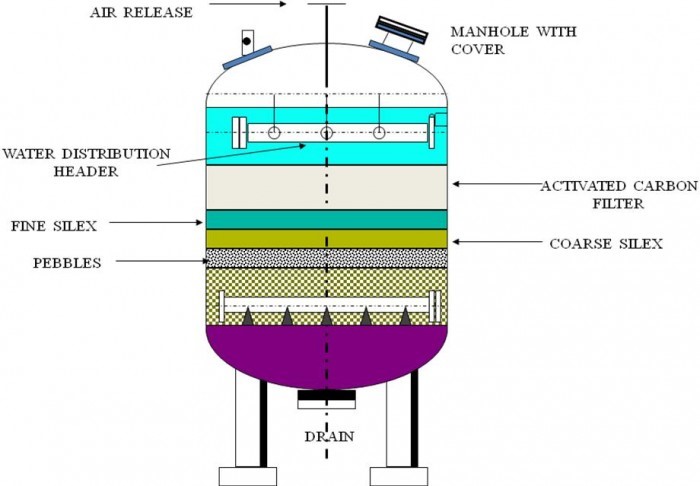

Activated Carbon Filter

Activated-carbon filtration is the process that is used to remove the organic compounds and chlorine from the water. The filters are designed in such a way as to remove free chlorine, organic matter, odor, and color. Carbon filtering works by adsorption, in which pollutants in the fluid to be treated are trapped inside the pore structure of a carbon substrate.

Target Impurities :-

1. Free Residual Chlorine2. Organic matter

3. Taste

4. Order

5. Color

Advantages :-

1. High Filtration efficiencies2. Filter up to 10 – 20 Microns

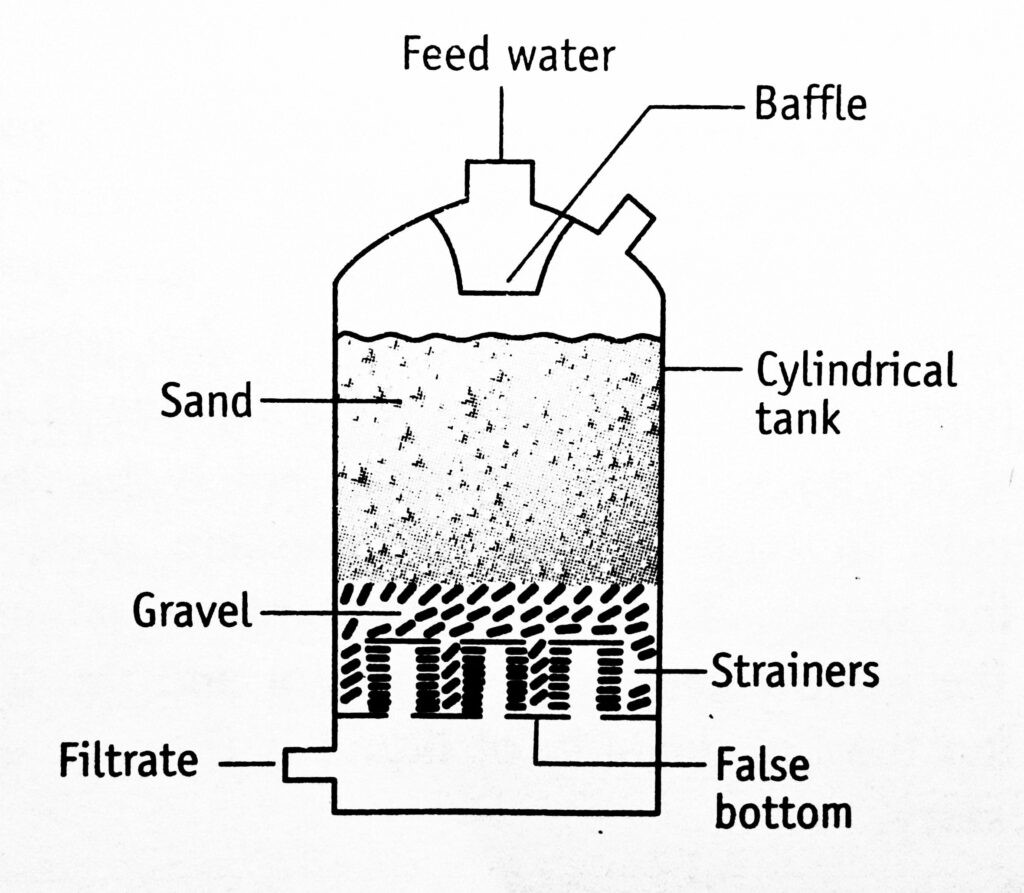

Pressure Sand Filter

The Pressure Sand Filter consists of a multiple layer of sand with a variety in size and specific gravity. These Filters are designed to remove turbidity and suspended particles present in the feed water with minimum pressure drop. Here Water is passed through multiple layers of graded sand, pebbles, and gravel layers in a pressure sand filtration.The media bed in the water filters the contaminants, and the filtered water then enters the discharge manifold, at the base of the containers.

Target Impurities :-

1. Suspended solids2. Turbidity

Advantages :-

1. Efficient Turbidity Removal2. Low Pressure drop across the vessel

Softener

Water softening is a technique that serves the removal of the ions that cause the water to be hard, in most cases calcium and magnesium ions. Iron ions may also be partially removed during softening. Hard water, in addition to forming scales in pipelines, equipment, appliances, and sanitary fittings, can have negative effects on human skin and hair. EWS Softeners are made up of rugged reinforced FRP Material. Our supplies are in association with choice of automatic / manual MPV for electrical pneumatic optical valves.

The main component of a water softner is a vessel loaded with resin particles that are coated in sodium ions. The resin bed serves as a magnet, attracting the calcium and magnesium ions, in return for the sodium ions as hard water passes through it. The resin beds eventually become saturated with mineral ions and must be "re-charged". This process in known as regeneration wherein a strong brine solution is pushed through the resin tank recharging the ions. When hard water passes through a water softener, it becomes soft water, which is the best drinking water and may be used for a variety of industrial purposes without causing any adverse effects.

Filter Layer: Sodium Based Resin

Target Impurities :-

1. Calcium2. Magnesium

3. Metal cations and anion

4. Hardness

Advantages :-

1. Water softening also reduces the irritation on hands and body.2. Assists in saving on expenses used to buy soap. Hard water makes very hard for efficient laundry. Therefore, a lot of soap must be utilized for lather formation.

3. Helps in recovering the shininess of the water.

4. There will be decreased water usage because soap forms lather quickly with the water.

5. No scale deposits will be formed in home appliances such as pipes and plastic water heaters.